Unique Three Pump Lift Stations

Current pump stations simply don't offer the efficient performance we need to preserve the environment. Global Green Lifts' unique three-pump lift stations outperforms traditional two-pump stations.

Start a Project With Us

Traditional Two Pump Lift Stations

For two-pump lift stations, pump horsepower must be large enough to handle the maximum wastewater inflow. This can result in low-efficiency pump operation and higher energy demand per start. If the primary pump fails, the backup pump must be of the same horsepower capacity to move the wastewater. Water Drop - Three-Pump Lift Stations Two high-horsepower pumps often experience periods of short cycling when the backup pump assists the primary pump due to the combined high gallons per minute outflow rate. Meanwhile, the primary motor turns on and off continuously, resulting in:

- Loss of kinetic energy per stop

- Heat buildup from motor stops

- Debris entering a stopped impeller, which causes excess resistant force on startups

- The motor burns out in a few years as a result of so many starts, stops, the increased heat, and the excess resistant force on startups

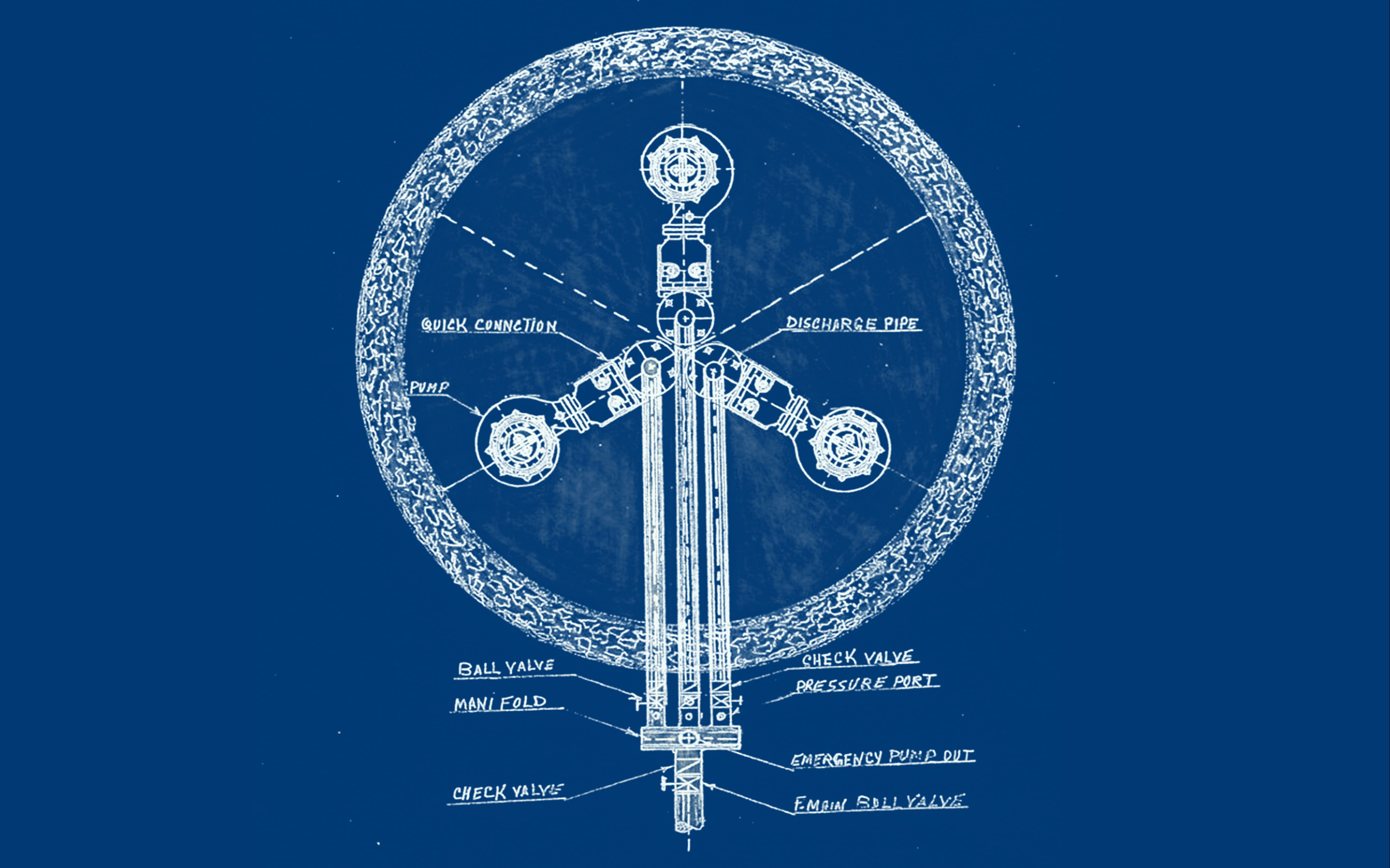

Efficient Green Three Pump Lift Stations

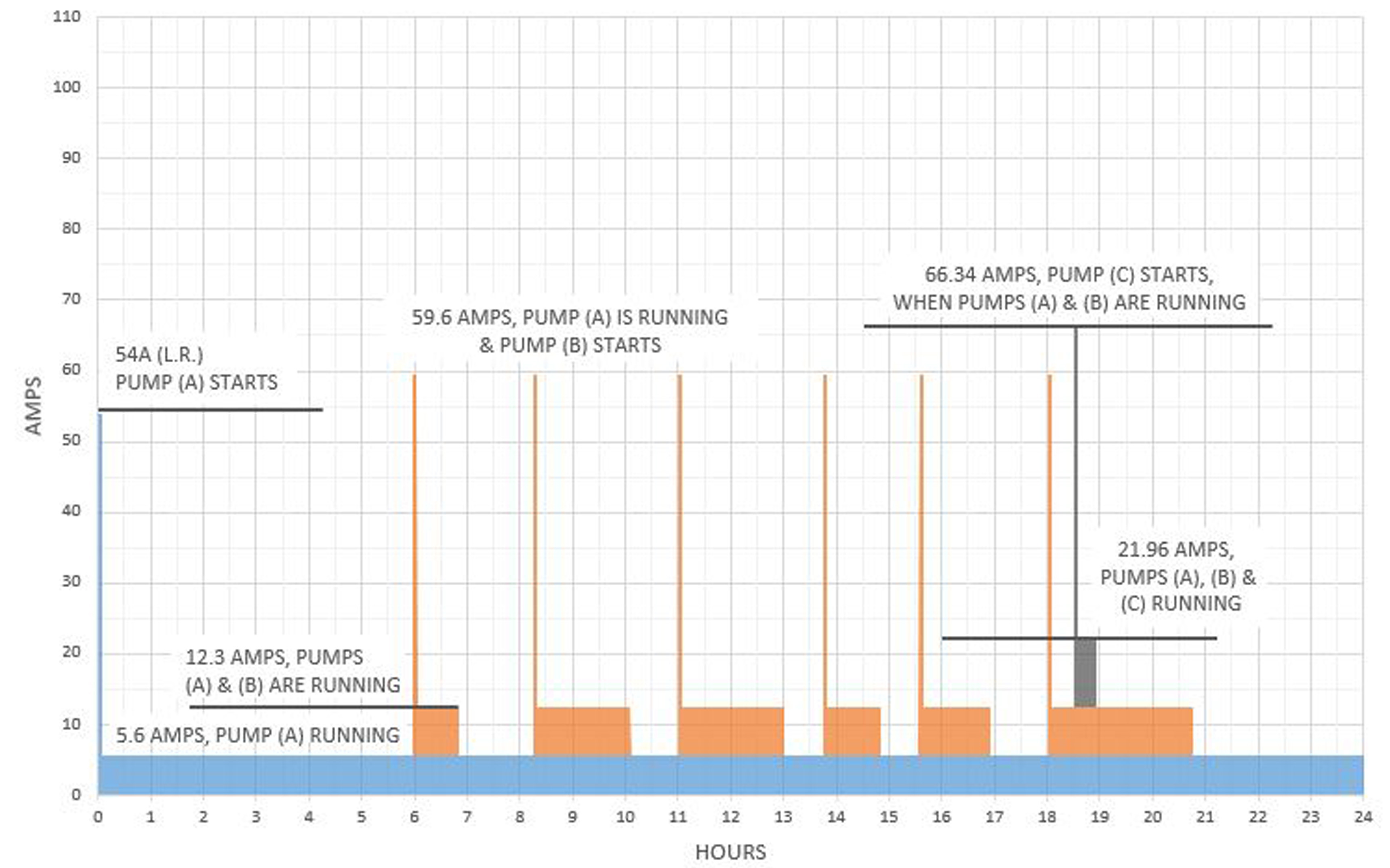

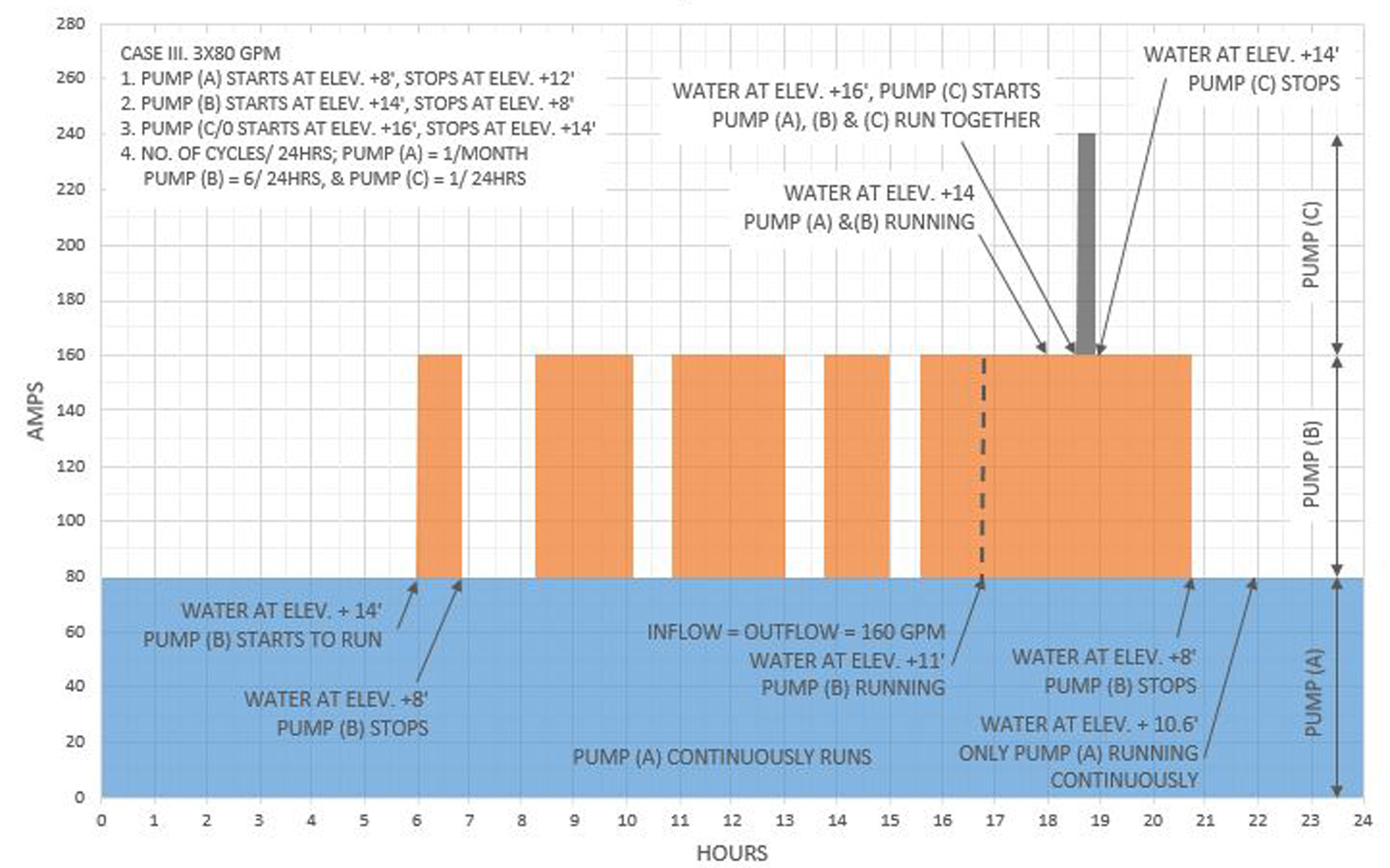

In three-pump lift stations, pump horsepower is based on the pump rated efficiency curve and impellers are trimmed as needed. This results in high efficiency pump operation and lower energy demand per start. The primary, backup, and standby pumps each have the same lowest possible horsepower, with the backup and standby pumps assisting the primary pump. Short cycling is thereby eliminated through the use of our patented control panel and the operating sequence of the low horsepower pumps. The primary pump runs continuously, while the backup pump turns on occasionally and the standby pump rarely runs. This setup means:

- Kinetic energy is maintained

- There is no motor stop heat buildup

- With the primary pump running continuously, debris does not settle against impellers

- The life of all three motors is maximized for the above three reasons, and the monthly three-pump operating sequence rotation is made possible by our control panel